#stacker window

Explore tagged Tumblr posts

Photo

Deck Roof Extensions in Sydney An illustration of a medium-sized, modern backyard deck with an addition to the roof

0 notes

Photo

Poolhouse - Modern Pool Pool house - large modern backyard custom-shaped pool house idea with decking

#wall cladding#viewing window#custom stacker doors#shaker cabinetry#black ceiling fans#outdoor kitchen#poolhouse

0 notes

Text

"Twisted Dandelion"

"This picture of a dandelion picked from my lawn was shot in my living room using a Mitutoyo10x microscope lens adapted to the camera using a 70-200mm f/4 lens as a tube lens. Using a motorized macro rail, I captured around 200 individual exposures that were combined in Zerene Stacker to produce the final image.

I often use such a setup to “poke around” inside dandelions. Using diffused light from a window to light the dandelion from behind creates a beautiful rim light, and better contrast, and makes the dandelion 'glow'."

By Harald Cederlund

Close-Up Photographer of the Year

19 notes

·

View notes

Text

Twilight Advent Calendar, Day 7

Dec. 7 - Choose one Twilight couple (or an AU ship) and tell us about an argument they've had. How did they resolve it in the end?

Masterpost/Prompts

I'm still fighting with this dang thing and have been for about a year. I was hoping to get it all the way unraveled with the help of a deadline but I did not. So here's a teaser of the surface of this fight. They are fighting about something that's actually two layers deeper than this, but it's going to take me a hot second to link this all up, apparently. ---

from "Yellows," Chapter 9 of Cien Años de Compañerismo

~||x||~

They hadn’t talked about this. They hadn’t needed to; vampires couldn’t reproduce sexually. She knew where he stood with respect to the legality of a medical procedure that he considered vital to his ability to care for his patients; he knew—and she thought, respected!—that he could never fathom what it was like to carry a pregnancy. But suddenly here they were, diametrically opposed.

Edward. It had only taken his conversation with Edward, and then they had been thrust into this nightmare. Always Edward. His weakest point; his fatal flaw. If Carlisle made a mistake, it was always for Edward. His rashest decisions—always with Edward in mind.

Except for you, her mind replied at once, and it was this reminder that softened her long enough to really look at him.

Her husband looked—anguished. If it were possible for him to somehow be paler, gaunter than he already was, he was that and then some. The light in his eyes that she loved, the playful side of him that he so rarely showed anyone but her, was utterly extinguished.

His eyes, darker than she’d seen them in a long while, cast around the nursery anxiously. He didn’t fully see it the first time, she knew. He took in the crib, the changing table, the diaper stacker, the blankets and rattles, the delicate lace and ornate woodwork mixed with the practicalities of size zero diapers and nipple pads and spit-up rags.

“You’ve done…a great deal,” he said finally.

No thanks to your overwhelming support, she wanted to say, but she did not. It was enough, she knew, to stand here, staring at him. Not comforting him, not taking him into her arms, not doing any of the things he’d come to rely on from her. She didn’t need to be cold to him; she needed only not to be warm.

“Well someone needed to do something.”

His brow furrowed. “Esme, I am doing everything.”

“You“—she choked. He was trying to figure it out, still. Still. Trying to get their daughter-in-law to see reason. Trying to make all this work, this room, this hope, utterly unnecessary. “Carlisle Cullen, you are still trying to end this.”

“I can’t end this!!!” he roared so loudly the window rattled a little, startling them both. The dark eyes went wide, and then her husband’s face disappeared into his palms. He had large hands, Carlisle, and he could bury all his features into them, leaving Esme staring at only the roots of his uncharacteristically untidy hair.

“Even if I wanted to, even if she wanted me to I couldn’t,” came the plaintive voice a moment later. “It—he—that—is growing too quickly. She’s so emaciated I can’t be certain but she measured at about twenty-six weeks this morning and twenty-eight this afternoon. Even if we were all agreed on what to do, even if I had decades of experience with this procedure—which I do not, may I remind you, try as you might to build me up as a monster in your head—I’d just as likely kill her anyway. There’s no target. I don’t know what I’m dealing with. I’m blind. And you…” he gulped. “You’re angry with me for what you think I’m doing but Esme, I can’t do anything at all.”

The repeated words rode on a quavering intake of breath as he locked her eyes: “I can’t do anything at all.”

She meant to take a step toward him, she thought, but her feet took her one step further away.

19 notes

·

View notes

Photo

TF Stacker Prototype Version 0.1 Released!

Seeing how popular that concept image was motivated me to throw together this bare-bones prototype of TF Stacker. It's only got the bare minimum features at the moment, but it can handle up to 10 different transformations and (presumably) all of the combo images that come with that. There's an undo button to undo the most recent transformation as well. The biggest draw to this prototype is that it's fully customizable, and without any coding knowledge required! I've provided a step-by-step process for creating your own image database that, when loaded into the game at the startup screen, allows you to play TF Stacker with whatever character and transformations you want! I've got a few different features I want to add to this later down the line, but for now I'm happy with what I was able to make. The project is currently designed around Windows 64-bit systems; I'm thinking about maybe trying to get it to work on Mac and Linux but that depends on how differently they handle their file systems. You can find everything you need to play and modify this prototype on the GitHub repo linked below! https://github.com/EV401SALVATION/TF-Stacker

Posted using PostyBirb

#game#game development#unity#transformation#dragon#inanimate#customizable#github#prototype#TF Stacker

9 notes

·

View notes

Text

"Could you describe her for me?"

Herc paused then, blinking at the quiet girl in front of him. The morning rain had left the air pleasant on the roofed gardens, rose-white clouds casting shadowed patterns throught the sides over the patch of grass where Herc and Mako sat in comfort. Stacker Pentecost, Marshall of the Hunter Order and father of the young girl, was absent that day. Only his voice and steel tone could be heard pass the garden walls as he commanded the training drills of the day.

Herc eyed his son sitting on one of the high windows on the wall above, pretending to be too busy supervising the training grounds to listen to his father's tale. Yet, Herc knew him better than that.

Describe Jazmine Becket.

If it wasn't evident, he had no expected to be asked of her. Yancy and Raleigh? Sure thing, his mouth was beginning to smile on his own every time some young girl or pal with blushy cheeks asked about the princeses. Are they as blond as we've heard of? Are their eyes as blue? Are they as handsome? As powerful? As charming? As rich? As funny? As kind?

At his age, Hercules Hansen was not a man of great passions anymore ---or at least he was not the type to publicly share them. Life had took his wife from his side and drove his brother crazy. The love he felt for them was a fresh wound in his chest, a particular nasty breed of grief and devotion and the Hansen way, old and worn as rock itself. No, he was not a man of flashing cards as he shuffled.

It didn't mean he was immune to the Becket fever, not in the least.

He had met them once, about two years ago. Herc had gone to Richard Becket's crowning ceremony, taking gifts from all the Beckets in the name of the King of the Wild, Herc's true title to the world. Chuck has stayed at home, not wanting to leave his mother side in case... In case she woke up. What if she opens her eyes and we are not by his side, dad? He had wailed, tucking his 12 years old frame into the space between her bed and the window. What if we come back and she's gone?

So Herc had travelled alone, unwilling to tell the truth to his only son: that his mother had fallen for a spell with no solution; that she will never wake up from her slumber; that he had the chance to wake up only one of them and he had given the antidote to Chuck.

Maybe that was what cemented his feelings for the Beckets at the time. The empty space where the Queen should sit, the goblets full of wine that tilted and stained the robes of the King every time he asked for a new drink. The eyes, sharp and oh-so-awake, of Prince Yancy Becket, meeting Herc's stare with the resolution of a 20 years old that knows his time is closer than anyone imagine.

In front of him, Pentecost's daugther folded together her hands on her lap, always polite as she waited for Herc to continue. Mako, he knew, was not much like any other kid from the outside. She must be 13 years old, a year or months younger than Chuck. Of course, he told himself, of course she wants to know about Jazmine. She must have heard of the other two from her father, but Pentecost had never met the youngest and brightest of the three. Jazmine had not become a knight, like her siblings, or a traveler, like her mother.

Chuck had one leg dangling from the side of the wall, the other bent at the knee to rest his forearm in it. Even with his back to them, Herc could read the interest of his son in the answer by the way Chuck had turned slightly in their direction. It was in his shoulders, and of course, in the fact Prince Hansen wouldn't miss the chance to know more about Raleigh Becket, his childhood hero.

"Young," his eyes fell from his son to the the Princess of the Hunters, blue bangs freshly dyed and hair cut shorter, "and diligent. She rules Anchorage while her brothers clean the land from monsters."

"How old is she?"

"16 years old, soon."

The wind picked up, forcing Herc to stop and Mako to hold her bangs out of her face. Fall in the Wild Lands was hotter than most, but Angela's ancestors had built the castle to let the wind run always placid, allowing the sun to land always true. His people used to said it was never blinding nor fastidious, often one shade away from your arse, something that made Herc cackle every time.

Nearing sunset hours now, the residuals of the early rain kept the gardens comfortable. Herc had loved that castle from the moment he saw it, when he was but a cadet walking inside the gates beside his brother Scott. He would never forget how the wind had picked up then too, carrying some delicate woman's handkerchief to Herc's grip. That's how he'd met Angela, blushing as she claimed it to be hers and teased him for following the wind of destiny when it called.

He wondered what such wind was trying to tell him. Above him, Chuck's shadow shifted.

"Is that all?"

Oh, yes. They were talking about Jazmine Becket, weren't them?

"I'm sorry, Miss Mori. I can't say much more from my experience. It's true she was there on her father's coronation, but the ladies and the dance kept her away most of the night. She was 15 years old and I, a man of war and politics, didn't want to bored the princess to no end."

Herc shook his head at the disappointment of his son and their companion, not wanting to aggravate them youngs more. Mako had distracted herself playing with the grass and Chuck had turned away completely, bored or pretending to be, muttering curses under his breath.

"Although I can tell you what I've heard of her in the tales the travelers had brought to me." Herc cought, keeping his laughther at bay as the teens faltered in their brooding. "In the South is hard to find true worda about her. It is our luck that the princeses seem unable to abandon their sister's memory at home as they change camps. Perhaps those stories will suffice your curiosity, miss Mori, if you're willing to wait for dinner to be served. As for now..."

Herc stood up. He could tell the answer by the light on Mako's eyes, the gentle curve of her lips forming a gracious smile. He'd try to get Chuck to join their conversation, as he knew his son would want to but never admit it in fear of making a fool of himself.

" ...I must go to confer with the Marshall the state of our knight force and the status of the upcoming operations. If you excuse me."

He exchanged bows with miss Mako, feeling more than seeing the moment Chuck landed on the grass and made his way to Herc's side. Together they marched from the gardens to the central towers, where Chuck would walk up to his chambers without a word said to his father and Herc would continue to the war room, waiting for Stacker to arrive.

#just something silly about one of my aus#I love fantasy settings and I love Herc povs#pacific rim#pacrim#pacific rim 2013#pacrim 2013#herc hansen#hercules hansen#angela hansen#chuck hansen#mako mori#stacker pentecost#raleigh becket#yancy becket#jazmine becket#richard becket#the hansens#the beckets#pacrim fantasy au#driftwithme.drabbles

7 notes

·

View notes

Text

wip whenever

Thanks @rowanisawriter for the tag!! I saw Pacific Rim a few months ago, and I've had this floating in my drafts:

///

Mako shops at farmer’s markets, spends her money on sour plum wine and juicy peaches, kicks off her shoes and lets her toes sink between her plush carpet, and tries to learn how to live without another person in her head. Sometimes she goes on dates, but they are short affairs; they bought time for everyone in the world except them. It’s frustrating having to fill in gaps, explain, and speak when before, just a pointed look or a touch could do. She's not sure she could call it a romance, with Raleigh, but there was something unshakable—an intimacy. The knowledge when she looked at him that he had crawled inside her mind and settled in the deepest parts of her.

It’s a good evening for a bath, to pour a glass of her wine and put the classical station on the radio, watching the moon rise through the window. There’s life in their world; like the cicadas, she’s resurfaced. Sometimes she dreams of going back to Hong Kong, burrowing into the ground for work. Herc is still there, Newt and Hermann, that little nest they cobbled together. She dips a foot into the water, and it’s too hot.

Stacker is not there. Stacker, who dragged her to an apartment in Kyoto, whose Japanese was never quite accented correctly; she used to laugh at him for it, before she understood just how much that little thinning of his lips held. Stacker, who lies in a watery grave underneath the crashing waves. With a deep breath, Mako slips into the tub and sinks beneath the water. She doesn’t come up until her lungs burn.

///

I'll tag anyone who wants to do this!!

6 notes

·

View notes

Text

Quality That Rolls Forward – Trusted Roll Forming Machines by Jugmug RollForming

In today’s rapidly evolving industrial landscape, precision, reliability, and innovation are the cornerstones of success. When it comes to metal forming, Jugmug RollForming stands tall as a beacon of engineering excellence. With decades of expertise and a relentless commitment to quality, Jugmug has redefined what roll forming means for manufacturers around the globe. Their machines are not just tools—they're solutions built to roll industries forward.

What Is Roll Forming and Why Does It Matter?

Roll forming is a continuous bending operation in which sheet metal is passed through a series of rollers to create desired cross-sections. The process is fast, efficient, and capable of producing high-strength components with tight tolerances. Industries ranging from construction to automotive, infrastructure to energy, rely on roll forming for their structural and precision part needs.

Whether it's roofing sheets, door frames, cable trays, solar panel structures, or highway guardrails, roll forming offers unmatched consistency, speed, and material utilization. And Jugmug RollForming ensures these advantages are delivered with industry-leading precision.

Why Choose Jugmug RollForming?

1. Commitment to Quality

At the heart of Jugmug’s philosophy lies a simple yet powerful idea—quality never goes out of style. Every machine is designed, engineered, and tested with stringent quality checks to ensure it meets both national and international standards. From raw material selection to final assembly, Jugmug leaves no stone unturned in delivering machines that last long and perform consistently.

2. Customization and Flexibility

One size does not fit all in industrial manufacturing. Jugmug RollForming understands this deeply and offers customized roll forming solutions tailored to specific requirements. Whether it’s a unique profile, a specific gauge range, or automation integration, Jugmug delivers solutions that fit your production goals perfectly.

3. State-of-the-Art Technology

Jugmug RollForming is at the forefront of technological advancement. From PLC and HMI control panels to servo-driven feeding systems and automatic stackers, their machines reflect the best in modern manufacturing. This not only ensures faster setup and changeover but also helps clients achieve higher throughput and efficiency.

4. Superior After-Sales Support

Jugmug’s commitment doesn’t end with the sale. They offer comprehensive support, including installation, training, troubleshooting, and maintenance. Their expert team is available to ensure your operations stay smooth and productive, helping you get maximum ROI from your investment.

Wide Range of Applications

Jugmug RollForming caters to an expansive list of industries, offering roll forming machines for a variety of applications:

Construction Industry: Roofing sheets, wall panels, purlins (C/Z/U shapes), door and window frames.

Energy Sector: Solar panel mounting structures, cable trays, and enclosures.

Infrastructure Projects: Highway guardrails, metal crash barriers, and road sign supports.

Storage and Racking: Shelving profiles, pallet racking systems.

Automotive & Transport: Bus body profiles, container parts, structural reinforcements.

Their machines are designed to handle various metals including galvanized steel, stainless steel, aluminum, and pre-painted materials—ensuring flexibility across product lines.

Engineering That Sets the Standard

Jugmug RollForming doesn’t just build machines—they build trust through engineering excellence. Their roll forming lines come equipped with:

High-precision rollers crafted from hardened steel for longer life

Hydraulic or pneumatic cutting systems for clean and accurate cuts

Decoilers and recoilers for seamless coil management

In-line punching and notching to reduce post-processing time

Optional automation features to scale up production

Each element of the roll forming machine is engineered with longevity and performance in mind, ensuring minimal downtime and consistent production.

Made in India, Trusted Worldwide

While Jugmug RollForming proudly manufactures its machinery in India, its reputation transcends borders. Their roll forming solutions have found customers in multiple countries thanks to their commitment to quality, cost-efficiency, and customer satisfaction.

By combining world-class engineering with localized support, Jugmug is helping businesses both big and small modernize their manufacturing processes.

Sustainability and Cost Efficiency

In addition to performance, Jugmug’s machines are built with a keen eye on energy efficiency and material optimization. Reduced waste, optimized forming speeds, and low maintenance needs help businesses stay sustainable and profitable.

Their machines also support modular upgrades, allowing businesses to add capabilities as they grow—making it a smart investment for startups and established industries alike.

The Future is Rolling – With Jugmug

As demand for faster, leaner, and smarter production rises, Jugmug RollForming is ready to meet the challenge. With ongoing R&D, customer-focused engineering, and a robust service network, Jugmug continues to be a trusted name in roll forming.

Their motto—“Quality That Rolls Forward”—is more than a tagline. It’s a reflection of the values that drive them every day: precision, reliability, and customer success.

Conclusion

In a competitive industrial environment, the tools you choose can define your growth. With Jugmug RollForming, you’re not just investing in a machine—you're partnering with a company that puts your success at the center of everything they do. From the first coil to the last cut, Jugmug ensures that quality keeps rolling forward.

0 notes

Text

Envision CTOS: A Next-Generation Container Terminal Operating System Transforming Port Operations

Introduction: The Urgency of Digital Transformation in Terminal Operations

Global seaports and inland terminals are at a strategic crossroads. Faced with increasing trade volumes, vessel mega-sizing, and a demand for faster throughput, traditional container terminal operations are being stretched beyond their limits. Manual processes, legacy software, and siloed data models are no longer sufficient to sustain the agility and efficiency required by today’s logistics ecosystem.

Enter Envision CTOS—a next-generation, AI-driven Container Terminal Operating System (CTOS) that transforms the way ports, inland container depots (ICDs), and container freight stations (CFSs) operate. More than just a tool for automation, Envision CTOS is a strategic platform built to empower intelligent decisions, unify multi-terminal operations, and drive measurable ROI.

In this in-depth blog, we explore how Envision CTOS is redefining container logistics through advanced technology integration, digital twin modeling, data intelligence, and seamless interoperability. Whether you’re a port authority, private terminal operator, or a logistics conglomerate managing multiple facilities, Envision CTOS provides the tools to lead in the era of smart ports.

Understanding Envision CTOS: An Overview

What is Envision CTOS?

Envision CTOS is a cloud-ready, modular, and highly scalable Container Terminal Operating System designed to manage and optimize the entire container terminal lifecycle. It goes far beyond the traditional scope of a TOS by incorporating:

AI & machine learning algorithms for dynamic decision-making

Digital twin simulation for planning and risk-free testing

Integrated mobility for remote and on-site task execution

Multi-terminal coordination for centralized control

Predictive analytics for anticipatory operations

Why Envision CTOS Matters

As the global logistics chain becomes increasingly digitized, real-time container tracking and tracing, intelligent container yard optimization, and integrated inland container depot (ICD) automation are essential. Envision CTOS is designed to address the complexity and scale of modern port environments while ensuring full transparency, traceability, and flexibility.

Core Functional Modules: How Envision CTOS Powers Smart Terminals

1. Vessel Planning and Berth Optimization

Efficient vessel planning is crucial for reducing port congestion and maximizing quay crane productivity. Envision CTOS Vessel Scheduler features:

AI-driven berth window recommendations

Real-time coordination with pilotage and tug services

Simulation of quay crane allocations

Scenario planning for delayed or out-of-window arrivals

This ensures optimal berth occupancy and reduces vessel idle time, supporting higher throughput during peak seasons.

2. Smart Yard Planning and Container Lifecycle Management

Yard management is the nerve center of terminal operations. Envision CTOS introduces dynamic yard allocation algorithms that:

Predict yard congestion

Suggest optimal stacking strategies

Integrate container priority based on export/import urgency

Auto-link with RTG, RMG, and reach stacker assignments

With live heatmaps and inventory snapshots, yard managers can reduce re-handling, minimize traffic paths, and improve container yard optimization and flow.

3. Gate and Truck Turnaround Automation

Gate operations are often a chokepoint. Envision CTOS integrates GateOps+, a module built for automated, secure, and speedy gate processing:

OCR for container number recognition

RFID-enabled driver check-ins

Pre-scheduled appointment systems

Queue management and dynamic rerouting

Combined, these innovations reduce average truck turnaround time by up to 35%, improving customer satisfaction and reducing pollution from idling vehicles. It also enhances container drayage management through real-time coordination.

4. Crane Productivity Monitoring and Control

Crane operations often determine the overall speed of vessel servicing. Envision CTOS offers:

Real-time crane performance dashboards

Automatic move counting and analytics

Crane clash detection and crane-to-vessel mapping

Shift-wise KPIs and utilization alerts

This module enables crane operators and supervisors to maintain optimal productivity while ensuring safety and alignment with operational goals.

The Role of AI and Machine Learning in Envision CTOS

Envision CTOS is not a static tool; it's a continuously learning platform. It uses historical and real-time data to power predictive models, including:

Vessel arrival delay prediction based on port congestion and sea traffic

Container dwell time forecasting using shipment profiles and port activity

Labor demand modeling to ensure cost-effective shift planning

Predictive maintenance for yard and handling equipment

These intelligent forecasts allow for pre-emptive resource allocation, better decision-making, and a shift from reactive to proactive terminal management. AI also enhances container tracking and tracing accuracy and operational efficiency.

Digital Twin Technology: Simulation-Driven Optimization

One of the most unique aspects of Envision CTOS is its Digital Twin Engine—a real-time simulation of the terminal’s operational and spatial layout. Terminal operators can simulate:

New container flow strategies

Equipment layout changes

Emergency evacuation scenarios

High-traffic conditions and peak-day planning

This allows management to experiment without disrupting real operations, increasing innovation and reducing risk. It plays a critical role in achieving empty container depot management efficiency.

Interconnectivity Across the Logistics Chain

In today’s fragmented logistics networks, a unified view across seaports, inland container depots (ICDs), and container freight stations (CFSs) is essential. Envision CTOS enables:

Real-time data exchange between facilities

Intermodal scheduling (rail-truck-container coordination)

Shared visibility on cargo movement and inventory

Customs clearance integration across nodes

This integrated architecture supports end-to-end import/export container logistics, reducing handoff delays and enhancing supply chain predictability.

Container Tracking and Tracing Capabilities

The SmartChain Tracker module in Envision CTOS ensures full visibility into container locations, status, and condition:

GPS and IoT-based real-time container tracking

Integration with shipping line EDI systems

Alerts for exceptions (e.g., lost, damaged, or misrouted containers)

Historical traceability for compliance and audits

This leads to better empty container depot management, lowers demurrage, and enhances customer trust through robust container tracking and tracing.

CFS and ICD Automation: Total Logistics Synchronization

For terminals with affiliated CFS and ICD operations, Envision CTOS brings specific modules that include:

Bonded cargo tracking and audit control

LCL/FCL split & merge management

Inspection, fumigation, and documentation status

Container drayage management and delivery scheduling

These features ensure holistic container freight station (CFS) management software capability and seamless inland container depot (ICD) automation, enabling terminals to eliminate silos and reduce overhead costs.

Smart Port Integration and IoT Enablement

Envision CTOS supports IoT integration to connect cranes, reach stackers, trucks, and sensors throughout the terminal. Features include:

Equipment telemetry and fault diagnostics

Condition-based asset monitoring

Smart lighting and energy management systems

Automated gate barriers and weighbridges

These integrations enable ports to transition into fully smart terminals with real-time responsiveness and system-wide optimization. This also enhances real-time container tracking and tracing and ensures better performance visibility.

Sustainability and ESG Compliance

Modern ports are increasingly judged on their environmental performance. Envision CTOS offers tools that support:

Monitoring of equipment fuel consumption and emissions

Real-time carbon footprint reporting

Optimization suggestions for green logistics practices

Support for electric and hybrid handling equipment integration

This helps terminals meet ESG targets and regulatory mandates without compromising performance. It also supports green initiatives in container depot software environments.

Multi-Terminal and Multi-Country Management

Large logistics companies operating across countries can deploy Envision CTOS MultiPort, a command and control tower to:

Benchmark performance across terminals

Transfer best practices between facilities

Standardize data reporting formats

Share assets (e.g., cranes, containers) for cost savings

This enables geographically distributed terminals to operate in synergy, maximizing the value of depot management system (DMS) and digital transformation across borders.

Envision CTOS in Numbers: Proven Benefits

Real-world deployments of Envision CTOS have delivered measurable results, including:

35–45% improvement in truck turnaround time

25–30% increase in crane productivity

30–50% reduction in manual documentation errors

70%+ visibility in real-time container location

50% faster response to operational disruptions

These metrics highlight how Envision CTOS and its integrated container depot software are proven drivers of operational excellence and competitive advantage.

Future-Ready Capabilities in Development

Envision CTOS is built with forward compatibility, and several cutting-edge features are in active development:

Drone integration for container scanning and yard surveillance

Blockchain-enabled digital handshakes for cargo milestones

AI-based co-pilot assistants for operations planners

Digital collaboration tools for shipping lines and customs agents

These advancements ensure that Envision CTOS evolves with industry trends, keeping your terminal ahead of the curve in depot management system (DMS) deployment and digital logistics.

Why Choose Envision CTOS?

In a world where container terminals are expected to operate with speed, precision, and transparency, Envision CTOS stands as a holistic solution that combines:

Deep domain expertise in port operations

Advanced technology architecture

Proven scalability for small to mega terminals

Local and global compliance readiness

24/7 support and rapid deployment capabilities

From onboarding to ROI realization, Envision CTOS is a partner in transformation, not just a technology vendor. It’s your ideal platform for modern container depot software, ICD automation, CFS management, and container yard optimization.

About Envision Enterprise Solutions

Envision Enterprise Solutions Pvt. Ltd. is a pioneer in port and logistics automation. With over two decades of expertise in deploying advanced systems for seaports, ICDs, and CFSs, Envision is recognized for:

Cutting-edge products like Envision CTOS

Specialized modules for depot management system (DMS), container yard optimization, and predictive logistics

Global clientele spanning Africa, Asia-Pacific, and the Middle East

Strong partnerships with terminal operators, shipping lines, and government bodies

Envision continues to push the boundaries of what's possible in smart logistics with next-gen container depot software and container tracking and tracing solutions.

Final Thoughts: Embrace the Future with Envision CTOS

As the global economy becomes more interconnected and digitized, container terminals need more than operational tools—they need strategic enablers. Envision CTOS is that enabler. With intelligent automation, real-time insights, full lifecycle tracking, and integrated inland logistics, it represents the future of port operations.

For terminal operators seeking to increase productivity, reduce costs, and deliver superior service, the journey to intelligent logistics begins with Envision CTOS.

Ready to transform your terminal operations? Contact Envision today or request a personalized demo of Envision CTOS to see how we can power your digital port transformation.

#container#artificial intelligence#terminals#ai powered solutions#ports#operating systems#envision#CTOS#maritime#maritime security#logistics#management

0 notes

Text

Envision CTOS: A Next-Generation Container Terminal Operating System Transforming Port Operations

Introduction: The Urgency of Digital Transformation in Terminal Operations

Global seaports and inland terminals are at a strategic crossroads. Faced with increasing trade volumes, vessel mega-sizing, and a demand for faster throughput, traditional container terminal operations are being stretched beyond their limits. Manual processes, legacy software, and siloed data models are no longer sufficient to sustain the agility and efficiency required by today’s logistics ecosystem.

Enter Envision CTOS — a next-generation, AI-driven Container Terminal Operating System (CTOS) that transforms the way ports, inland container depots (ICDs), and container freight stations (CFSs) operate. More than just a tool for automation, Envision CTOS is a strategic platform built to empower intelligent decisions, unify multi-terminal operations, and drive measurable ROI.

In this in-depth blog, we explore how Envision CTOS is redefining container logistics through advanced technology integration, digital twin modeling, data intelligence, and seamless interoperability. Whether you’re a port authority, private terminal operator, or a logistics conglomerate managing multiple facilities, Envision CTOS provides the tools to lead in the era of smart ports.

Understanding Envision CTOS: An Overview

What is Envision CTOS?

Envision CTOS is a cloud-ready, modular, and highly scalable Container Terminal Operating System designed to manage and optimize the entire container terminal lifecycle. It goes far beyond the traditional scope of a TOS by incorporating:

AI & machine learning algorithms for dynamic decision-making

Digital twin simulation for planning and risk-free testing

Integrated mobility for remote and on-site task execution

Multi-terminal coordination for centralized control

Predictive analytics for anticipatory operations

Why Envision CTOS Matters

As the global logistics chain becomes increasingly digitized, real-time container tracking and tracing, intelligent container yard optimization, and integrated inland container depot (ICD) automation are essential. Envision CTOS is designed to address the complexity and scale of modern port environments while ensuring full transparency, traceability, and flexibility.

Core Functional Modules: How Envision CTOS Powers Smart Terminals

1. Vessel Planning and Berth Optimization

Efficient vessel planning is crucial for reducing port congestion and maximizing quay crane productivity. Envision CTOS Vessel Scheduler features:

AI-driven berth window recommendations

Real-time coordination with pilotage and tug services

Simulation of quay crane allocations

Scenario planning for delayed or out-of-window arrivals

This ensures optimal berth occupancy and reduces vessel idle time, supporting higher throughput during peak seasons.

2. Smart Yard Planning and Container Lifecycle Management

Yard management is the nerve center of terminal operations. Envision CTOS introduces dynamic yard allocation algorithms that:

Predict yard congestion

Suggest optimal stacking strategies

Integrate container priority based on export/import urgency

Auto-link with RTG, RMG, and reach stacker assignments

With live heatmaps and inventory snapshots, yard managers can reduce re-handling, minimize traffic paths, and improve container yard optimization and flow.

3. Gate and Truck Turnaround Automation

Gate operations are often a chokepoint. Envision CTOS integrates GateOps+, a module built for automated, secure, and speedy gate processing:

OCR for container number recognition

RFID-enabled driver check-ins

Pre-scheduled appointment systems

Queue management and dynamic rerouting

Combined, these innovations reduce average truck turnaround time by up to 35%, improving customer satisfaction and reducing pollution from idling vehicles. It also enhances container drayage management through real-time coordination.

4. Crane Productivity Monitoring and Control

Crane operations often determine the overall speed of vessel servicing. Envision CTOS offers:

Real-time crane performance dashboards

Automatic move counting and analytics

Crane clash detection and crane-to-vessel mapping

Shift-wise KPIs and utilization alerts

This module enables crane operators and supervisors to maintain optimal productivity while ensuring safety and alignment with operational goals.

The Role of AI and Machine Learning in Envision CTOS

Envision CTOS is not a static tool; it’s a continuously learning platform. It uses historical and real-time data to power predictive models, including:

Vessel arrival delay prediction based on port congestion and sea traffic

Container dwell time forecasting using shipment profiles and port activity

Labor demand modeling to ensure cost-effective shift planning

Predictive maintenance for yard and handling equipment

These intelligent forecasts allow for pre-emptive resource allocation, better decision-making, and a shift from reactive to proactive terminal management. AI also enhances container tracking and tracing accuracy and operational efficiency.

Digital Twin Technology: Simulation-Driven Optimization

One of the most unique aspects of Envision CTOS is its Digital Twin Engine — a real-time simulation of the terminal’s operational and spatial layout. Terminal operators can simulate:

New container flow strategies

Equipment layout changes

Emergency evacuation scenarios

High-traffic conditions and peak-day planning

This allows management to experiment without disrupting real operations, increasing innovation and reducing risk. It plays a critical role in achieving empty container depot management efficiency.

Interconnectivity Across the Logistics Chain

In today’s fragmented logistics networks, a unified view across seaports, inland container depots (ICDs), and container freight stations (CFSs) is essential. Envision CTOS enables:

Real-time data exchange between facilities

Intermodal scheduling (rail-truck-container coordination)

Shared visibility on cargo movement and inventory

Customs clearance integration across nodes

This integrated architecture supports end-to-end import/export container logistics, reducing handoff delays and enhancing supply chain predictability.

Container Tracking and Tracing Capabilities

The SmartChain Tracker module in Envision CTOS ensures full visibility into container locations, status, and condition:

GPS and IoT-based real-time container tracking

Integration with shipping line EDI systems

Alerts for exceptions (e.g., lost, damaged, or misrouted containers)

Historical traceability for compliance and audits

This leads to better empty container depot management, lowers demurrage, and enhances customer trust through robust container tracking and tracing.

CFS and ICD Automation: Total Logistics Synchronization

For terminals with affiliated CFS and ICD operations, Envision CTOS brings specific modules that include:

Bonded cargo tracking and audit control

LCL/FCL split & merge management

Inspection, fumigation, and documentation status

Container drayage management and delivery scheduling

These features ensure holistic container freight station (CFS) management software capability and seamless inland container depot (ICD) automation, enabling terminals to eliminate silos and reduce overhead costs.

Smart Port Integration and IoT Enablement

Envision CTOS supports IoT integration to connect cranes, reach stackers, trucks, and sensors throughout the terminal. Features include:

Equipment telemetry and fault diagnostics

Condition-based asset monitoring

Smart lighting and energy management systems

Automated gate barriers and weighbridges

These integrations enable ports to transition into fully smart terminals with real-time responsiveness and system-wide optimization. This also enhances real-time container tracking and tracing and ensures better performance visibility.

Sustainability and ESG Compliance

Modern ports are increasingly judged on their environmental performance. Envision CTOS offers tools that support:

Monitoring of equipment fuel consumption and emissions

Real-time carbon footprint reporting

Optimization suggestions for green logistics practices

Support for electric and hybrid handling equipment integration

This helps terminals meet ESG targets and regulatory mandates without compromising performance. It also supports green initiatives in container depot software environments.

Multi-Terminal and Multi-Country Management

Large logistics companies operating across countries can deploy Envision CTOS MultiPort, a command and control tower to:

Benchmark performance across terminals

Transfer best practices between facilities

Standardize data reporting formats

Share assets (e.g., cranes, containers) for cost savings

This enables geographically distributed terminals to operate in synergy, maximizing the value of depot management system (DMS) and digital transformation across borders.

Envision CTOS in Numbers: Proven Benefits

Real-world deployments of Envision CTOS have delivered measurable results, including:

35–45% improvement in truck turnaround time

25–30% increase in crane productivity

30–50% reduction in manual documentation errors

70%+ visibility in real-time container location

50% faster response to operational disruptions

These metrics highlight how Envision CTOS and its integrated container depot software are proven drivers of operational excellence and competitive advantage.

Future-Ready Capabilities in Development

Envision CTOS is built with forward compatibility, and several cutting-edge features are in active development:

Drone integration for container scanning and yard surveillance

Blockchain-enabled digital handshakes for cargo milestones

AI-based co-pilot assistants for operations planners

Digital collaboration tools for shipping lines and customs agents

These advancements ensure that Envision CTOS evolves with industry trends, keeping your terminal ahead of the curve in depot management system (DMS) deployment and digital logistics.

Why Choose Envision CTOS?

In a world where container terminals are expected to operate with speed, precision, and transparency, Envision CTOS stands as a holistic solution that combines:

Deep domain expertise in port operations

Advanced technology architecture

Proven scalability for small to mega terminals

Local and global compliance readiness

24/7 support and rapid deployment capabilities

From onboarding to ROI realization, Envision CTOS is a partner in transformation, not just a technology vendor. It’s your ideal platform for modern container depot software, ICD automation, CFS management, and container yard optimization.

About Envision Enterprise Solutions

Envision Enterprise Solutions Pvt. Ltd. is a pioneer in port and logistics automation. With over two decades of expertise in deploying advanced systems for seaports, ICDs, and CFSs, Envision is recognized for:

Cutting-edge products like Envision CTOS

Specialized modules for depot management system (DMS), container yard optimization, and predictive logistics

Global clientele spanning Africa, Asia-Pacific, and the Middle East

Strong partnerships with terminal operators, shipping lines, and government bodies

Envision continues to push the boundaries of what’s possible in smart logistics with next-gen container depot software and container tracking and tracing solutions.

Final Thoughts: Embrace the Future with Envision CTOS

As the global economy becomes more interconnected and digitized, container terminals need more than operational tools — they need strategic enablers. Envision CTOS is that enabler. With intelligent automation, real-time insights, full lifecycle tracking, and integrated inland logistics, it represents the future of port operations.

For terminal operators seeking to increase productivity, reduce costs, and deliver superior service, the journey to intelligent logistics begins with Envision CTOS.

Ready to transform your terminal operations? Contact Envision today or request a personalized demo of Envision CTOS to see how we can power your digital port transformation.

#artificial intelligence#container#ports#terminals#logistics#envision#freight#manufacturing#iotsolutions#ctos

0 notes

Text

Envision CTOS: A Next-Generation Container Terminal Operating System

Introduction: The Urgency of Digital Transformation in Terminal Operations

Global seaports and inland terminals are at a strategic crossroads. Faced with increasing trade volumes, vessel mega-sizing, and a demand for faster throughput, traditional container terminal operations are being stretched beyond their limits. Manual processes, legacy software, and siloed data models are no longer sufficient to sustain the agility and efficiency required by today’s logistics ecosystem.

Enter Envision CTOS — a next-generation, AI-driven Container Terminal Operating System (CTOS) that transforms the way ports, inland container depots (ICDs), and container freight stations (CFSs) operate. More than just a tool for automation, Envision CTOS is a strategic platform built to empower intelligent decisions, unify multi-terminal operations, and drive measurable ROI.

In this in-depth blog, we explore how Envision CTOS is redefining container logistics through advanced technology integration, digital twin modeling, data intelligence, and seamless interoperability. Whether you’re a port authority, private terminal operator, or a logistics conglomerate managing multiple facilities, Envision CTOS provides the tools to lead in the era of smart ports.

Understanding Envision CTOS: An Overview

What is Envision CTOS?

Envision CTOS is a cloud-ready, modular, and highly scalable Container Terminal Operating System designed to manage and optimize the entire container terminal lifecycle. It goes far beyond the traditional scope of a TOS by incorporating:

AI & machine learning algorithms for dynamic decision-making

Digital twin simulation for planning and risk-free testing

Integrated mobility for remote and on-site task execution

Multi-terminal coordination for centralized control

Predictive analytics for anticipatory operations

Why Envision CTOS Matters

As the global logistics chain becomes increasingly digitized, real-time container tracking and tracing, intelligent container yard optimization, and integrated inland container depot (ICD) automation are essential. Envision CTOS is designed to address the complexity and scale of modern port environments while ensuring full transparency, traceability, and flexibility.

Core Functional Modules: How Envision CTOS Powers Smart Terminals

1. Vessel Planning and Berth Optimization

Efficient vessel planning is crucial for reducing port congestion and maximizing quay crane productivity. Envision CTOS Vessel Scheduler features:

AI-driven berth window recommendations

Real-time coordination with pilotage and tug services

Simulation of quay crane allocations

Scenario planning for delayed or out-of-window arrivals

This ensures optimal berth occupancy and reduces vessel idle time, supporting higher throughput during peak seasons.

2. Smart Yard Planning and Container Lifecycle Management

Yard management is the nerve center of terminal operations. Envision CTOS introduces dynamic yard allocation algorithms that:

Predict yard congestion

Suggest optimal stacking strategies

Integrate container priority based on export/import urgency

Auto-link with RTG, RMG, and reach stacker assignments

With live heatmaps and inventory snapshots, yard managers can reduce re-handling, minimize traffic paths, and improve container yard optimization and flow.

3. Gate and Truck Turnaround Automation

Gate operations are often a chokepoint. Envision CTOS integrates GateOps+, a module built for automated, secure, and speedy gate processing:

OCR for container number recognition

RFID-enabled driver check-ins

Pre-scheduled appointment systems

Queue management and dynamic rerouting

Combined, these innovations reduce average truck turnaround time by up to 35%, improving customer satisfaction and reducing pollution from idling vehicles. It also enhances container drayage management through real-time coordination.

4. Crane Productivity Monitoring and Control

Crane operations often determine the overall speed of vessel servicing. Envision CTOS offers:

Real-time crane performance dashboards

Automatic move counting and analytics

Crane clash detection and crane-to-vessel mapping

Shift-wise KPIs and utilization alerts

This module enables crane operators and supervisors to maintain optimal productivity while ensuring safety and alignment with operational goals.

The Role of AI and Machine Learning in Envision CTOS

Envision CTOS is not a static tool; it’s a continuously learning platform. It uses historical and real-time data to power predictive models, including:

Vessel arrival delay prediction based on port congestion and sea traffic

Container dwell time forecasting using shipment profiles and port activity

Labor demand modeling to ensure cost-effective shift planning

Predictive maintenance for yard and handling equipment

These intelligent forecasts allow for pre-emptive resource allocation, better decision-making, and a shift from reactive to proactive terminal management. AI also enhances container tracking and tracing accuracy and operational efficiency.

Digital Twin Technology: Simulation-Driven Optimization

One of the most unique aspects of Envision CTOS is its Digital Twin Engine — a real-time simulation of the terminal’s operational and spatial layout. Terminal operators can simulate:

New container flow strategies

Equipment layout changes

Emergency evacuation scenarios

High-traffic conditions and peak-day planning

This allows management to experiment without disrupting real operations, increasing innovation and reducing risk. It plays a critical role in achieving empty container depot management efficiency.

Interconnectivity Across the Logistics Chain

In today’s fragmented logistics networks, a unified view across seaports, inland container depots (ICDs), and container freight stations (CFSs) is essential. Envision CTOS enables:

Real-time data exchange between facilities

Intermodal scheduling (rail-truck-container coordination)

Shared visibility on cargo movement and inventory

Customs clearance integration across nodes

This integrated architecture supports end-to-end import/export container logistics, reducing handoff delays and enhancing supply chain predictability.

Container Tracking and Tracing Capabilities

The SmartChain Tracker module in Envision CTOS ensures full visibility into container locations, status, and condition:

GPS and IoT-based real-time container tracking

Integration with shipping line EDI systems

Alerts for exceptions (e.g., lost, damaged, or misrouted containers)

Historical traceability for compliance and audits

This leads to better empty container depot management, lowers demurrage, and enhances customer trust through robust container tracking and tracing.

CFS and ICD Automation: Total Logistics Synchronization

For terminals with affiliated CFS and ICD operations, Envision CTOS brings specific modules that include:

Bonded cargo tracking and audit control

LCL/FCL split & merge management

Inspection, fumigation, and documentation status

Container drayage management and delivery scheduling

These features ensure holistic container freight station (CFS) management software capability and seamless inland container depot (ICD) automation, enabling terminals to eliminate silos and reduce overhead costs.

Smart Port Integration and IoT Enablement

Envision CTOS supports IoT integration to connect cranes, reach stackers, trucks, and sensors throughout the terminal. Features include:

Equipment telemetry and fault diagnostics

Condition-based asset monitoring

Smart lighting and energy management systems

Automated gate barriers and weighbridges

These integrations enable ports to transition into fully smart terminals with real-time responsiveness and system-wide optimization. This also enhances real-time container tracking and tracing and ensures better performance visibility.

Sustainability and ESG Compliance

Modern ports are increasingly judged on their environmental performance. Envision CTOS offers tools that support:

Monitoring of equipment fuel consumption and emissions

Real-time carbon footprint reporting

Optimization suggestions for green logistics practices

Support for electric and hybrid handling equipment integration

This helps terminals meet ESG targets and regulatory mandates without compromising performance. It also supports green initiatives in container depot software environments.

Multi-Terminal and Multi-Country Management

Large logistics companies operating across countries can deploy Envision CTOS MultiPort, a command and control tower to:

Benchmark performance across terminals

Transfer best practices between facilities

Standardize data reporting formats

Share assets (e.g., cranes, containers) for cost savings

This enables geographically distributed terminals to operate in synergy, maximizing the value of depot management system (DMS) and digital transformation across borders.

Envision CTOS in Numbers: Proven Benefits

Real-world deployments of Envision CTOS have delivered measurable results, including:

35–45% improvement in truck turnaround time

25–30% increase in crane productivity

30–50% reduction in manual documentation errors

70%+ visibility in real-time container location

50% faster response to operational disruptions

These metrics highlight how Envision CTOS and its integrated container depot software are proven drivers of operational excellence and competitive advantage.

Future-Ready Capabilities in Development

Envision CTOS is built with forward compatibility, and several cutting-edge features are in active development:

Drone integration for container scanning and yard surveillance

Blockchain-enabled digital handshakes for cargo milestones

AI-based co-pilot assistants for operations planners

Digital collaboration tools for shipping lines and customs agents

These advancements ensure that Envision CTOS evolves with industry trends, keeping your terminal ahead of the curve in depot management system (DMS) deployment and digital logistics.

Why Choose Envision CTOS?

In a world where container terminals are expected to operate with speed, precision, and transparency, Envision CTOS stands as a holistic solution that combines:

Deep domain expertise in port operations

Advanced technology architecture

Proven scalability for small to mega terminals

Local and global compliance readiness

24/7 support and rapid deployment capabilities

From onboarding to ROI realization, Envision CTOS is a partner in transformation, not just a technology vendor. It’s your ideal platform for modern container depot software, ICD automation, CFS management, and container yard optimization.

About Envision Enterprise Solutions

Envision Enterprise Solutions Pvt. Ltd. is a pioneer in port and logistics automation. With over two decades of expertise in deploying advanced systems for seaports, ICDs, and CFSs, Envision is recognized for:

Cutting-edge products like Envision CTOS

Specialized modules for depot management system (DMS), container yard optimization, and predictive logistics

Global clientele spanning Africa, Asia-Pacific, and the Middle East

Strong partnerships with terminal operators, shipping lines, and government bodies

Envision continues to push the boundaries of what’s possible in smart logistics with next-gen container depot software and container tracking and tracing solutions.

Final Thoughts: Embrace the Future with Envision CTOS

As the global economy becomes more interconnected and digitized, container terminals need more than operational tools — they need strategic enablers. Envision CTOS is that enabler. With intelligent automation, real-time insights, full lifecycle tracking, and integrated inland logistics, it represents the future of port operations.

For terminal operators seeking to increase productivity, reduce costs, and deliver superior service, the journey to intelligent logistics begins with Envision CTOS.

Ready to transform your terminal operations? Contact Envision today or request a personalized demo of Envision CTOS to see how we can power your digital port transformation.

#terminals#maritime#ai powered solutions#container#smart ports#artificial intelligence#envision#logistics#management#ports#envision CTOS

0 notes

Text

Style and Performance of Black Aluminium Windows

Black aluminium windows are the window frames made from aluminium that are finished in a sleek black color. They are popular in modern architecture due to their combination of style, durability, and low maintenance. Here are some key characteristics:

Key Features of Black Aluminium Windows

Material: Made from aluminium, which is lightweight yet strong, offering excellent structural integrity.

Finish: Typically coated with a durable powder coating that enhances resistance to corrosion, fading, and scratches, maintaining the black color over time.

Design: Available in various styles, including casement, sliding, and fixed windows, allowing for flexibility in design and functionality.

Energy Efficiency: Many models incorporate thermal breaks and double or triple glazing to improve insulation, reducing energy costs.

Aesthetic Appeal: The black finish provides a contemporary and elegant look, making them suitable for various architectural styles.

Customization: They can be tailored in size and shape, making them versatile for different types of buildings.

Energy Efficiency

Thermal Performance: Many black aluminium windows feature thermal breaks, which help improve insulation and energy efficiency, keeping homes warmer in winter and cooler in summer.

Sustainability: Aluminium is a recyclable material, and using energy-efficient designs can contribute to more sustainable building practices.

Design Flexibility

Customization: These windows can be customized in terms of size, shape, and style, allowing for creative design solutions that fit unique spaces.

Frameless Options: Some designs offer minimalistic frames that maximize glass area, enhancing natural light and views.

Installation and Cost

Professional Installation: Proper installation is crucial for maximizing the benefits of black aluminium windows, so hiring experienced professionals is recommended.

Price Range: While they can be more expensive than traditional materials like vinyl or wood, their longevity and aesthetic benefits often justify the investment.

Conclusion

Black aluminium windows are a stylish and practical choice for modern architecture. Their sleek appearance enhances the visual appeal of any building, while their durability and low maintenance make them a long-lasting investment. With excellent energy efficiency and customizable options, they cater to a wide range of design preferences and requirements. Whether for residential or commercial use, black aluminium windows provide a perfect blend of form and function, making them an ideal solution for those seeking both aesthetics and performance.

0 notes

Text

The Ultimate Guide To Choosing A Retractable Flyscreen In Australia

Australia’s warm climate and love for outdoor living make fresh air and natural ventilation essential parts of everyday life. However, the country’s abundance of insects—from buzzing flies to persistent mozzies—can turn an open door into a pest invasion. That’s where a retractable flyscreen in Australia proves its value. Designed for modern homes, these innovative screens allow airflow without compromising on comfort, aesthetics, or convenience. In this guide, we explore the features, benefits, and considerations for installing retractable flyscreens across Australian homes.

Understanding Retractable Flyscreens

What Sets Them Apart

Unlike traditional fixed mesh, a retractable flyscreen operates on a discreet track or cassette system, allowing it to be extended when needed and concealed when not. Whether manually operated or spring-loaded, these screens offer a seamless solution for doors and windows of all shapes and sizes.

A Fit for Every Region in Australia

Whether you’re in coastal Queensland, urban Sydney, or the rural outskirts of Victoria, insects are a constant challenge. Installing a retractable flyscreen in Australia ensures you can keep your home open to nature without letting the pests in—perfect for the varied climates across the country.

Benefits of Retractable Flyscreens

Superior Ventilation Without Compromise

Retractable screens encourage natural airflow, reducing your reliance on artificial cooling. This improves indoor air quality and cuts down energy costs. Plus, since they can be rolled away when not in use, they never block light or views.

Stylish and Space-Saving

Modern flyscreens are designed to be nearly invisible when retracted, maintaining clean architectural lines. Unlike fixed screens that can look dated or bulky, retractable options are subtle and contemporary, making them ideal for open-plan and design-conscious homes.

Types of Screens Available Across Australia

Sliding and Pull-Across Screens

These are most popular for large doorways such as bi-folds, stackers, and patio doors. The mesh glides horisontally along a track, offering a wide span with minimal effort. They’re ideal for entertaining areas and backyards that open to the outdoors.

Roll-Down Screens for Windows

Designed for vertical use, these roll down from the top and neatly retract into a cassette when not needed. They’re perfect for windows in kitchens, bedrooms, and bathrooms—especially where maintaining an external view is important.

What to Look for When Choosing a Retractable Flyscreen

Mesh Options and Protection Levels

Mesh quality matters especially in Australia, where durability and visibility are key. Standard fibreglass is budget-friendly, but options like pet-resistant mesh or solar mesh are available for added strength and UV protection. In bushfire-prone areas, bushfire-compliant mesh is essential.

Frame Materials and Colour Matching

Aluminium frames are commonly used for their strength and rust resistance. Ensure your flyscreen frame is powder-coated to withstand Australia’s harsh climate. Many suppliers allow custom colour matching, so your screen blends into the door or window frame for a polished finish.

Installation and Aftercare

Professional Installation Across Australia

While DIY kits exist, professional installers ensure precision measurements, expert fitting, and smooth operation. Whether you’re in a city apartment or a suburban home, professionals who install retractable flyscreens in Australia often offer tailored solutions based on location and layout.

Maintenance for Long-Term Use

Routine care involves brushing dust from tracks, checking for debris, and wiping down the mesh with a soft cloth. Avoid using harsh chemicals, and ensure the retraction mechanism operates smoothly. With proper care, a high-quality retractable flyscreen can last many years.

Conclusion

In a country where outdoor living is a way of life, a retractable flyscreen in Australia is more than a luxury—it’s a necessity. Offering the perfect blend of functionality, style, and flexibility, these screens allow Australians to enjoy the breese without the bugs. Whether you're upgrading a modern city home or retrofitting a regional property, retractable flyscreens enhance both comfort and practicality, making them a worthwhile investment for any household.

0 notes

Text

7 Ways to Optimize the Design of a Cold Storage Warehouse

Designing an efficient cold storage warehouse is crucial for businesses that rely on maintaining the quality and safety of temperature-sensitive products. Here are seven strategies to optimize the design of a cold storage warehouse:

1. Strategic Location and Orientation

The location and orientation of a cold storage facility significantly impact its energy efficiency. Position the building to minimize exposure to direct sunlight, particularly on critical walls and windows. Consider prevailing wind patterns for passive ventilation and utilize natural shade from trees or water bodies to maintain a cooler environment around the facility.

2. Utilize Advanced Automation Systems

Incorporating automation into warehouse design can enhance efficiency and reduce labor costs. Selecting an automation system before finalizing the building design allows for better integration, maximizing storage capabilities. Automated systems such as stacker cranes and robotic pallet shuttles can significantly improve retrieval processes and overall throughput.

3. Maximize Vertical Space

Building taller warehouses can help reduce the footprint while increasing storage capacity. High-density storage solutions, such as automated storage and retrieval systems (AS/RS), allow for efficient use of vertical space, minimizing energy consumption associated with cooling larger areas.

4. Implement Effective Insulation

Proper insulation is essential for maintaining temperature control in cold storage facilities. Use high-quality insulation materials to minimize heat exchange between the internal environment and external conditions. This not only helps in maintaining desired temperatures but also reduces energy costs associated with refrigeration.

5. Optimize Temperature Monitoring Systems

Integrating advanced temperature monitoring systems can ensure that products remain within their required temperature ranges. Utilizing IoT sensors allows for real-time tracking of temperature and humidity levels, enabling quick responses to any fluctuations that could compromise product integrity.

6. Design Efficient Loading and Unloading Areas

Loading bays in warehouse design layouts should be spacious enough to accommodate multiple delivery vehicles simultaneously, reducing congestion and improving operational efficiency. Wider doors and lanes facilitate easier access for trucks, allowing for quicker loading and unloading processes, which is vital for time-sensitive deliveries

7. Incorporate Sustainable Practices

Adopting sustainable practices in cold storage design can lead to long-term cost savings and environmental benefits. This includes using eco-friendly refrigerants, optimizing cooling systems for energy efficiency, and implementing renewable energy sources like solar panels. Regular maintenance checks are also necessary to ensure systems operate at peak efficiency.

By implementing these strategies, businesses can create cold storage warehouses and warehouse design layouts that not only meet operational demands but also enhance energy efficiency and sustainability, ultimately leading to improved profitability in the competitive market of temperature-sensitive goods.

0 notes

Text

Our Plans Are Set—This Must Be SOLD!

- 35 Raithburn Terrace Pokeno

"Yes...Our future plans are firmly in place, we want this Sold". Our owners are embarking on an exciting move across the Tasman and are offering you an incredible opportunity to own this "peace of mind" Solid Brick 4 Bedroom beauty by Platinum Homes. Grab the opportunity to own this impressive home before someone else does—missing out is simply not an option! Whether you’re a first-time buyer or a seasoned homeowner, this stylish and functional modern home is ready for you to move in, relax, and enjoy. With motivated sellers eager to see a SOLD sign, now is the time to act!

Why You’ll Love This Home:

Entertainer’s Dream: The designer kitchen, complete with quality appliances, ample storage, and a breakfast bar that flows seamlessly into the dining and living areas. Stacker doors open to a timber deck featuring a spa pool—perfect for indoor-outdoor entertaining.

Spacious & Practical: Four bedrooms, including a master with ensuite, plus thoughtful storage solutions.

Effortless Living: Enjoy the convenience of an internal-access double garage with remote access, off-street parking, and a fully fenced, low-maintenance freehold section spanning 602m² (mol).

Features At A Glance

Floor Area: 179m² (approx.), single level.

Solid brick construction with a metal tile roof and double-glazed aluminum windows.

Designer kitchen with quality appliances.

Two bathrooms, including an ensuite.

Spa pool, Heat pump, burglar alarm & CCTV Cameras for comfort and security.

Fully landscaped, low-maintenance garden beds.

Prime Location – Pokeno Perfection

Nestled in the heart of Pokeno, this home offers the charm of a country lifestyle without sacrificing convenience. Nestled at the foot of the Bombay Hills and protected by the surrounding terrain. Pokeno is strategically located at the crossroads of State Highways 1 and 2, boasting convenient access to the north and south, the Coromandel, Bay of Plenty and West Coast beaches. Strategically in the middle of Hamilton and Auckland CBDs. 10 minutes to Pukekohe, 20 minutes to Manukau City, 45 km to Auckland CBD, and 72 km to Hamilton.

"Escape the hustle of city life—this opportunity won’t last long!" Our vendors have new plans and clear instructions to SELL. Take the first step toward better living. Call NOW!

Ajay Gulati - Barfoot & Thompson- 021 236 2008

#SolidBrick #DeadlineSale #SellitNow #ClearInstructions #EntertainersDream #BarfootandThompson Barfoot & Thompson Manukau #RealEstate #GULATI #RaithburnTerrace #Pokeno Ajay Gulati @highlight

https://www.barfoot.co.nz/905299

0 notes

Photo

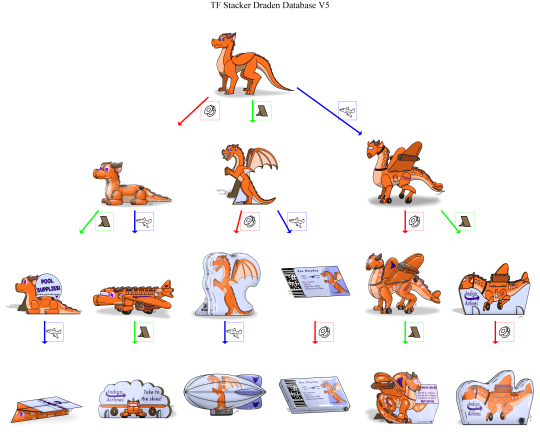

TF Stacker Draden Database V5

I've updated the Draden Database on TF Stacker's itch.io page to version 5, which includes all of the images for the three transformations currently listed in it. For anyone not familiar TF Stacker is a transformation "game" that functions more like an interactive art challenge and viewer. The game itself asks you to supply the path to a database of images and assets, and then allows you to click different buttons to transform a character in different ways. The order that you choose the TFs matters, and there are a ton of different possible combinations that can be made. The real game of TF Stacker is making and sharing databases with your own characters and transformations. The game supports up to ten transformations of your choice, which can result in almost 10 million different combinations! You can even change up the UI and music, and add backgrounds that can be cycled through. Unfortunately, while I had originally intended to release this alongside an update making it more accessible to different platforms, I ran into some difficulties and lack of knowledge that sapped my motivation to do so. As such the game will still be Windows exclusive for the foreseeable future, though I may come back and give porting it to other platforms another shot in the future. You can find the game, database, and other information at the following link: https://donhp.itch.io/tf-stacker

Posted using PostyBirb

2 notes

·

View notes